GxP Data Integrity And Computer Systems

GxP Data Integrity And Computer Systems

GxP Data Integrity And Computer Systems

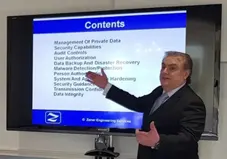

System Consultancy Services Delivered By An Experienced Consultant

Computer System Consultancy Services Delivered By An Experienced Consultant

Computer System Consultancy Services Delivered By An Experienced Consultant

Data Integrity Is Currently A Regulatory Hot Topic!

Are Your Electronic Records

And Electronic Signatures Secure?

Need Help With 21 CFR Part 11 Compliance?

For GxP applications, Data Integrity

arrangements must ensure that the accuracy, completeness, content and meaning of data are retained throughout the data lifecycle.

The way in which regulatory data is generated has continued to evolve in line with the introduction and ongoing development of supporting technologies, supply chains and ways of working. Systems to support these ways of working can range from manual processes with paper records to the use of computerised systems. However, the main purpose of the regulatory requirements remains the same; having confidence in the quality and the integrity of the data generated and being able to reconstruct activities remain fundamental requirements.

Systems and processes should be designed in a way that encourages compliance with the principles of data integrity. Consideration should be given to ease of access, usability and location whilst ensuring appropriate control of the activity guided by the criticality of the data.

Need Bespoke Training in Data Integrity Delivered by Current Industry Experts?

Data Integrity Is Currently A Regulatory Hot Topic!

Are Your Electronic Records

And Electronic Signatures Secure?

Need Help With 21 CFR Part 11 Compliance?

For GxP applications, Data Integrity arrangements must ensure that the accuracy, completeness, content and meaning of data are retained throughout the data lifecycle.

The way in which regulatory data is generated has continued to evolve in line with the introduction and ongoing development of supporting technologies, supply chains and ways of working. Systems to support these ways of working can range from manual processes with paper records to the use of computerised systems. However, the main purpose of the regulatory requirements remains the same; having confidence in the quality and the integrity of the data generated and being able to reconstruct activities remain fundamental requirements.

Systems and processes should be designed in a way that encourages compliance with the principles of data integrity. Consideration should be given to ease of access, usability and location whilst ensuring appropriate control of the activity guided by the criticality of the data.

Need Bespoke Training in Data Integrity Delivered by Current Industry Experts?

Data Integrity Is Currently A Regulatory Hot Topic!

Are Your Electronic Records

And Electronic Signatures Secure?

Need Help With 21 CFR Part 11 Compliance?

For GxP applications, Data Integrity arrangements must ensure that the accuracy, completeness, content and meaning of data are retained throughout the data lifecycle.

The way in which regulatory data is generated has continued to evolve in line with the introduction and ongoing development of supporting technologies, supply chains and ways of working. Systems to support these ways of working can range from manual processes with paper records to the use of computerised systems. However, the main purpose of the regulatory requirements remains the same; having confidence in the quality and the integrity of the data generated and being able to reconstruct activities remain fundamental requirements.

Systems and processes should be designed in a way that encourages compliance with the principles of data integrity. Consideration should be given to ease of access, usability and location whilst ensuring appropriate control of the activity guided by the criticality of the data.

Need Bespoke Data Integrity Training Delivered By Current Industry Experts?

Who Is Responsible For Data Integrity?

Senior management is responsible for the implementation of systems and procedures to minimise the potential risk to data integrity, and for identifying the residual risk.

Routine data reviews should evaluate the integrity of an individual data set, compliance with established organisational and technical measures and any data risk indicators.

Where GxP computerised systems are used to capture, process, report, store and archive raw data electronically, system design should always provide for the retention of audit trails to show all changes to the data while retaining previous and original data. Electronic Records and Electronic Signatures (ERES) must provide Integrity.

Backup and recovery processes should be validated and periodically tested.

For information on GxP computer systems and databases

ZES have validated to ensure Data Integrity, click below:

Who Is Responsible For Data Integrity?

Senior management is responsible for the implementation of systems and procedures to minimise the potential risk to data integrity, and for identifying the residual risk.

Routine data reviews should evaluate the integrity of an individual data set, compliance with established organisational and technical measures and any data risk indicators.

Where GxP computerised systems are used to capture, process, report, store and archive raw data electronically, system design should always provide for the retention of audit trails to show all changes to the data while retaining previous and original data.

Electronic Records and Electronic Signatures (ERES) must provide integrity.

Backup and recovery processes should be validated and periodically tested.

For information on

GxP computer systems and databases

ZES have validated to ensure

Data Integrity, click below:

Who Is Responsible For Data Integrity?

Senior management is responsible for the implementation of systems and procedures to minimise the potential risk to data integrity, and for identifying the residual risk.

Routine data reviews should evaluate the integrity of an individual data set, compliance with established organisational and technical measures and any data risk indicators.

Where GxP computerised systems are used to capture, process, report, store and archive raw data electronically, system design should always provide for the retention of audit trails to show all changes to the data while retaining previous and original data.

Electronic Records and Electronic Signatures (ERES) must provide integrity.

Backup and recovery processes should be validated and periodically tested.

For information on GxP

computer systems and databases

ZES have validated to ensure

Data Integrity, click below:

Data Integrity Audits Performed By ZES

Regulatory Authorities require Life Science manufacturing organisations to take responsibility for the computer systems utilised during manufacturing operations and the GxP Data they generate.

Life Science manufacturing organisations are expected to implement, design and operate a documented system that provides an acceptable state of control based on a documented Data Integrity Risk Assessment supported by a sound rationale.

The organisational culture should ensure that the generated data is complete, consistent and accurate in all its forms, i.e. paper and electronic.

Zener Engineering Services Ltd (ZES)

perform Data Integrity audits against the latest Regulatory Requirements and Guidance. If Data Integrity weaknesses are identified, ZES support the manufacturer to ensure that appropriate corrective and preventive actions are implemented across all relevant activities and systems.

The ZES Data Integrity Audit

includes, but is not limited to, the following subject matters:

- ALCOA+

- Data Life Cycle

- Company Culture

- Data Governance

- Data Organisation

- Regulatory Updates

- System and Process Design

- Data Integrity Supporting Processes

- Data Criticality and Inherent Integrity Risk

Need a Data Integrity Audit Performed by a Current Industry Expert?

Data Integrity Audits Performed By ZES

Regulatory Authorities require Life Science manufacturing organisations to take responsibility for the computer systems utilised during manufacturing operations and the GxP Data they generate.

Life Science manufacturing organisations are expected to implement, design and operate a documented system that provides an acceptable state of control based on a documented Data Integrity Risk Assessment supported by a sound rationale.

The organisational culture should ensure that the generated data is complete, consistent and accurate in all its forms, i.e. paper and electronic.

Zener Engineering Services Ltd (ZES)

perform Data Integrity audits against the latest Regulatory Requirements and Guidance. If Data Integrity weaknesses are identified, ZES support the manufacturer to ensure that appropriate corrective and preventive actions are implemented across all relevant activities and systems.

The ZES Data Integrity Audit

includes, but is not limited to, the following subject matters:

- ALCOA+

- Company Culture

- System and Process Design

- Data Integrity Supporting Processes

- Data Criticality and Inherent Integrity Risk

- Data Life Cycle

- Data Governance

- Data Organisation

- Regulatory Updates

Need a Data Integrity Audit Performed by a Current Industry Expert?

Data Integrity Audits Performed By ZES

Regulatory Authorities require Life Science manufacturing organisations to take responsibility for the computer systems utilised during manufacturing operations and the GxP Data they generate.

Life Science manufacturing organisations are expected to implement, design and operate a documented system that provides an acceptable state of control based on a documented Data Integrity Risk Assessment supported by a sound rationale.

The organisational culture should ensure that the generated data is complete, consistent and accurate in all its forms, i.e. paper and electronic.

Zener Engineering Services Ltd (ZES)

perform Data Integrity audits against the latest Regulatory Requirements and Guidance. If Data Integrity weaknesses are identified, ZES support the manufacturer to ensure that appropriate corrective and preventive actions are implemented across all relevant activities and systems.

The ZES Data Integrity Audit

includes, but is not limited to, the following subject matters:

- ALCOA+

- Company Culture

- System and Process Design

- Data Integrity Supporting Processes

- Data Criticality and Inherent Integrity Risk

- Data Life Cycle

- Data Governance

- Data Organisation

- Regulatory Updates

Need a Data Integrity Audit Performed by a Current Industry Expert?

Testimonials From Various Satisfied GxP Clients

Testimonial

Data Integrity Audit Report:

Following the submission of a 37-page Data Integrity Audit Report from ZES, the client provided feedback, part of which is quoted below:

"........ turns out that on a national level the BMS [Building Management System] has never been validated by [supplier organisation removed]. So we have opened up a can of worms for them! [Organisation removed] are arranging each centre in the country to validate it.."

Confidential

COVID Treatment Provider

Testimonial

Pharmaceutical Manufacturing: DCS CSV

"I worked with David [of Zener Engineering Services] on a project to deliver an ABB 800XA DCS system for a Blue Chip Pharmaceutical company. He was the QA lead for the supplier.

We jointly reviewed and approved a very large FAT document set in lieu of a reduced SAT and OQ. David's approach is very professional, critical, but crucially pragmatic.

I enjoyed working with him and would welcome any future opportunities to do so."

Steve Del-Bianco

Computer Systems Validation Analyst

GlaxoSmithKline GMS WARE

Testimonial

Pharmaceutical Manufacturing: DCS CSV

"I worked with David [of Zener Engineering Services] on a project to deliver an ABB 800XA DCS system for a Blue Chip Pharmaceutical company. He was the QA lead for the supplier.

We jointly reviewed and approved a very large FAT document set in lieu of a reduced SAT and OQ. David's approach is very professional, critical, but crucially pragmatic.

I enjoyed working with him and would welcome any future opportunities to do so."

Steve Del-Bianco

Computer Systems Validation Analyst

GlaxoSmithKline GMS WARE

Data Integrity Guides For Download

Data Integrity Guides For Download

MHRA’s GxP Data Integrity Guide 2018

Guidance for the UK

The GxP data integrity guidance has a high degree of alignment with documents published by other regulators such as PIC/S, WHO, OECD (guidance and advisory documents on GLP) and EMA. It is designed to facilitate compliance through education, whilst clarifying the MHRA’s position on data integrity and the minimum expectation to achieve compliance.

MHRA’s GxP Data Integrity Guide 2018

Guidance for the UK

The GxP Data Integrity guidance has a high degree of alignment with documents published by other regulators such as PIC/S, WHO, OECD (guidance and advisory documents on GLP) and EMA. It is designed to facilitate compliance through education, whilst clarifying the MHRA’s position on data integrity and the minimum expectation to achieve compliance.

FDA's Data Integrity And Compliance

With Drug cGMP 2018

Guidance for the USA

The FDA guidance aimed at helping drug manufacturers ensure data integrity and product safety. The document is an update to the FDA's 2016 draft guidance on the topic and will ensure industry compliance with current good manufacturing practice (cGMP).

If you need help implementing policies and procedure to achieve a good level of compliance, ZES experts are happy to help. Download the guidance here:

For all your Policies, SOPs and Protocol Templates

GxP Products For Sale

Visit our Products for Sale page for all your GxP documentation templates.

For all your Policies, SOPs and Protocol Templates

GxP Products For Sale

Visit our Products for Sale page for all your GxP documentation templates.

Data Integrity Frequently Asked Questions

Zener Engineering Services Ltd answer your Data Integrity questions.

-

What is Data Integrity in Pharma?

Data integrity is key in the pharmaceutical industry to ensure that the end products meet the required quality standards. It is the process of maintenance and assurance of accuracy and consistency of the data over its entire life cycle.

-

How do you Manage Data Integrity?

Data has Integrity depending on the accuracy of the information, including its authenticity and trustworthiness.

Consider the following when managing data integrity:

- Whether data is accurate and uncorrupted

- Whether data can be modified only by approved personnel, under certain conditions

- Whether data has come only from specific, trusted sources

Data integrity and data availability are both factors in data's criticality, or how essential that data is to the manufacturers operations.

-

What are the types of Electronic Records?

Examples of electronic records include:

- Emails

- Websites

- Word/Excel documents

- Digital purchase receipts

- Databases

- Information stored on Share Point sites and content management systems (Catalyst, Slack, DropBox, etc.).

-

What are the Characteristics of Electronic Records?

There are four essential characteristics:

- Authenticity: A record must be what it purports to be.

- Reliability: A record must be a full and accurate representation of the transactions, activities, or facts to which it attests.

- Integrity: A record must be complete and unaltered.

- Usability: A record must be able to be located, retrieved, presented, and interpreted.

-

What does ALCOA+ stand for?

ALCOA is an acronym meaning:

- Attributable

- Legible

- Contemporaneous

- Original

- Accurate

The '+' means:

- Complete

- Consistent

- Enduring

- Available

Data Integrity Frequently Asked Questions

Zener Engineering Services Ltd answer your Data Integrity questions.

-

What is Data Integrity in Pharma?

Data integrity is key in the pharmaceutical industry to ensure that the end products meet the required quality standards. It is the process of maintenance and assurance of accuracy and consistency of the data over its entire life cycle.

-

How do you Manage Data Integrity?

Data has Integrity depending on the accuracy of the information, including its authenticity and trustworthiness.

Consider the following when managing data integrity:

- Whether data is accurate and uncorrupted

- Whether data can be modified only by approved personnel, under certain conditions

- Whether data has come only from specific, trusted sources

Data integrity and data availability are both factors in data's criticality, or how essential that data is to the manufacturers operations.

-

What are the types of Electronic Records?

Examples of electronic records include:

- Emails

- Websites

- Word/Excel documents

- Digital purchase receipts

- Databases

- Information stored on Share Point sites and content management systems (Catalyst, Slack, DropBox, etc.).

-

What are the Characteristics of Electronic Records?

There are four essential characteristics:

- Authenticity: A record must be what it purports to be.

- Reliability: A record must be a full and accurate representation of the transactions, activities, or facts to which it attests.

- Integrity: A record must be complete and unaltered.

- Usability: A record must be able to be located, retrieved, presented, and interpreted.

-

What does ALCOA+ stand for?

ALCOA is an acronym meaning:

- Attributable

- Legible

- Contemporaneous

- Original

- Accurate

The '+' means:

- Complete

- Consistent

- Enduring

- Available

Zener Engineering Services Ltd

Data Integrity

GxP computer systems and Data Integrity?

Need Training in Data Integrity?

ZES have helped many satisfied clients.

Contact ZES for a Data Integrity Consultant.

Zener Engineering Services Ltd

Data Integrity

Do you have concerns about your

GxP computer systems and Data Integrity?

Need Training in Data Integrity?

ZES have helped many satisfied clients.

Contact ZES for a Data Integrity Consultant.

Zener Engineering Services Ltd

Data Integrity

Do you have concerns

about your GxP computer systems

and Data Integrity?

ZES have helped many

satisfied clients.

Contact ZES for a

Data Integrity Consultant.